Engineering

100% US-Based Engineering

Engineering excellence has been at the core of X-ES since its founding. We design, configure, test, and support all products at our headquarters in Verona, Wisconsin, where we’ve built a dynamic team with wide-ranging expertise in embedded computing. Thanks to a long-standing partnership with the the University of Wisconsin-Madison College of Engineering, we continue to keep the team staffed with top talent as the company grows.

At X-ES, engineers work not only on product design, but also in project management and executive roles. We maintain a flat management structure that helps us stay focused on engineering competence while responding quickly to new challenges.

Driving Innovation with In-House Talent

X-ES strives to keep all engineering functions under one roof—including roles that are often outsourced by other companies.

Here are some examples of why it matters.

![]()

In-House PCB Design

Working with an in-house PCB team improves outcomes in several areas.

For example, power supply engineers can optimize via placement to ensure proper current paths; signal integrity engineers can adjust routes to achieve the latest-generation signal rates; and the mechanical team can advise on component placement early in the design process to mitigate thermal, shock, and vibration risks.

![]()

In-House Qualification Testing

X-ES performs on-site thermal, shock, vibration, altitude, and humidity testing.

Because we control these assets in-house, we can also pre-screen prototypes during the development process to expose potential flaws prior to formal qualification, reducing schedule risk and speeding product development times.

![]()

In-House Software Development

Our in-house software development team works closely with hardware engineers and can provide the latest drivers and software technologies without employing third-party vendors.

From bootloader development to operating system support, X-ES will work with you to create a robust platform so you can focus on your application. When issues arise, you can count on prompt resolution from a single source.

Fast Turnaround with Modular Design

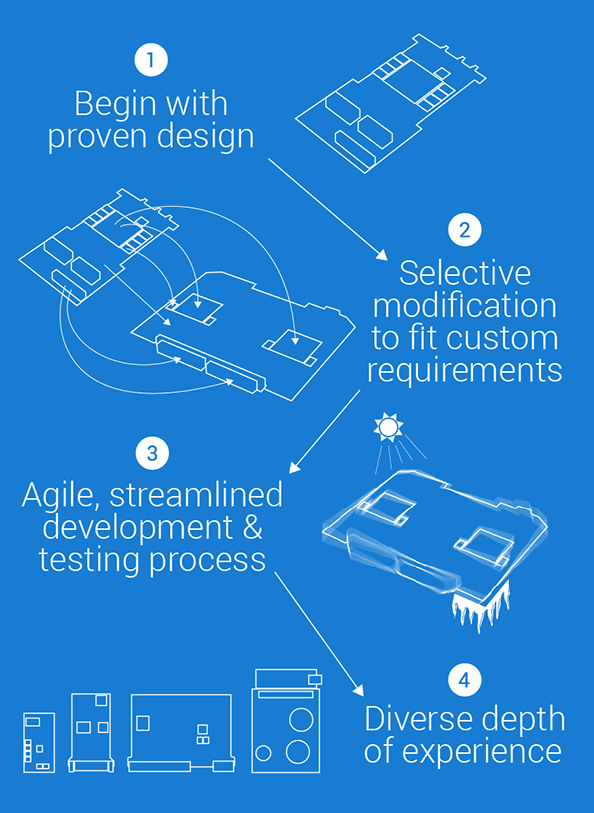

X-ES has earned a reputation for delivering custom products at industry-leading speeds. How do we do it? There are many factors at play, but if we had to identify one “secret ingredient,” it would be our modular design methodology.

Design reuse is the key to this approach. Whenever possible, our engineers reuse proven schematics and layouts, rather than starting from scratch for each project. They modify functionality only as needed based on custom requirements, which streamlines the design, testing, and manufacturing of new products.

The principle of modular design also applies when moving new processor technologies from one form factor to another. By adding or removing functionality only as needed based on form factor, we reduce the time it takes to develop standard products that support the latest processor technologies across eight industry-standard form factors (3U VPX, 6U VPX, 3U cPCI, 6U cPCI, 6U VME, XMC, PMC, and COM Express).

Benefits of modular design include:

- Fast turnaround of derivative and custom designs

- Fast adoption of new processor technologies

- Lower risk of introducing new hardware design flaws

- Lower risk of introducing new software bugs

- Fewer manufacturing defects, higher yields, and faster delivery

- Better software support due to consistency of board support packages across form factors

Proactive Quality Management

X-ES follows a structured, yet lightweight design process that includes multiple quality reviews and has been rated best-in-class by the International Organization for Standardization (ISO). Our ISO 9001-certified quality management system is focused not only on addressing current issues, but also on improving performance. We continuously apply metrics to help evaluate performance and find ways to do our jobs better.

Committed to Customer Success

Customers have direct access to the engineers who worked on their products throughout the product life cycle, ensuring that issues are resolved as efficiently as possible. We also have a dedicated support team that responds to general inquiries with a guaranteed response time of four hours or less.