Ruggedization

Rugged Done Right

This isn’t “in case you drop your laptop” rugged. X-ES delivers embedded computing solutions for military, aerospace, and industrial applications where harsh conditions over extended periods are the rule, not the exception.

We use best-in-class methodologies to ensure that our products operate reliably in extremes of temperature, shock, vibration, and environment. Our in-house manufacturing and environmental testing facilities help us achieve quick turnaround and strict quality control, following processes certified to the ISO 9001 standard.

![]()

Advanced Cooling

Thermal management is key to any ruggedization approach, particularly as deployed applications continue to require more processing power and higher bandwidth. Our products incorporate the latest air- or conduction-cooling techniques to help optimize performance.

We select an appropriate cooling method for each product based on the operating environment and size requirements. We implement these methods according to the relevant industry standards (for example, VITA 48 for VPX systems), making exceptions for custom designs when necessary.

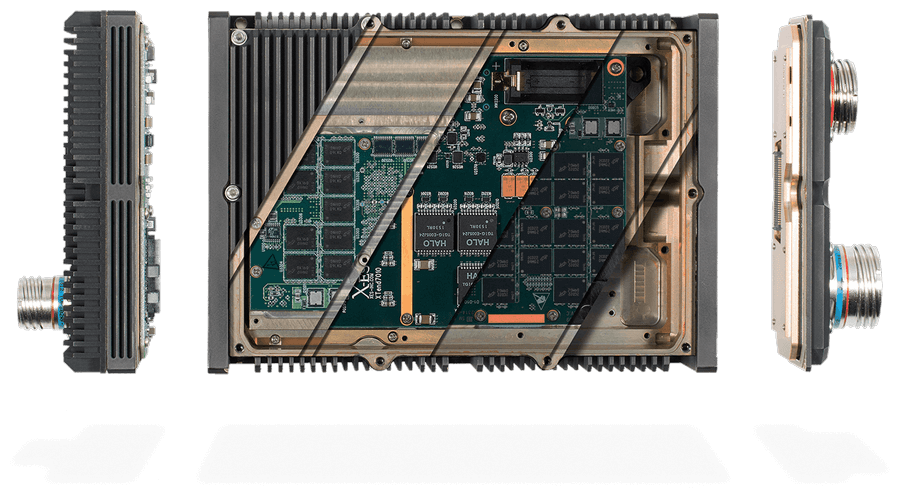

Rugged Design

X-ES hardware includes a number of features to enhance durability and longevity, such as:

- High-quality components rated for an extended temperature range

- Integrated stiffening frames and thermal management assemblies

- Memory that is soldered to the board

- Leaded solder

- Conformal coatings

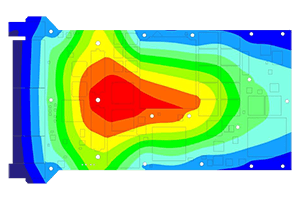

Mechanical engineers are involved early in every design, providing an important “reality check” and flagging any thermal or structural issues. For new designs or customizations that are deemed especially risky, they run thermal and structural simulations to predict performance under the expected operating conditions.

![]()

Systematic Testing

All X-ES products undergo a formal acceptance test procedure (ATP), which includes thorough testing of all interfaces. We also perform environmental qualification testing (EQT) per the product’s ruggedization level and acceptance criteria, which typically involves temperature, shock, and vibration testing to the relevant military or industry standards. EQT might include additional testing, such as humidity or altitude, to meet program requirements.

As part of the manufacturing process, we complete environmental stress screening (ESS) for every deployable unit delivered. The level of ESS varies based on customer needs. If a product has components that are not rated for the product’s operating temperature range, we also perform temperature uprate screening (TUS).

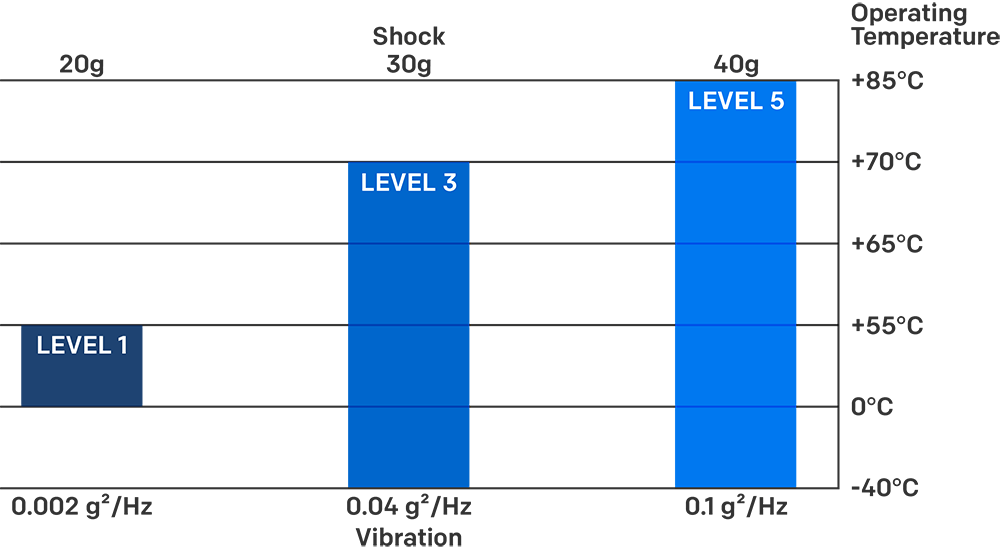

Ruggedization Levels

X-ES products are available in three ruggedization levels, allowing customers to balance environmental requirements with cost considerations:

- Standard air-cooled (Level 1) is for commercial-grade products used in benign operating environments or application development.

- Rugged air-cooled (Level 3) is for products that need to operate over a wider temperature range than standard commercial products. It also offers increased shock and vibration tolerance.

- Conduction-cooled (Level 5) is for the most rugged applications. It has the widest operating temperature range and the strongest protection against shock and vibration.

Refer to the tables below for detailed specifications. If an application doesn’t fit into one of these levels, we can design to custom requirements.